Anim1Block - 1

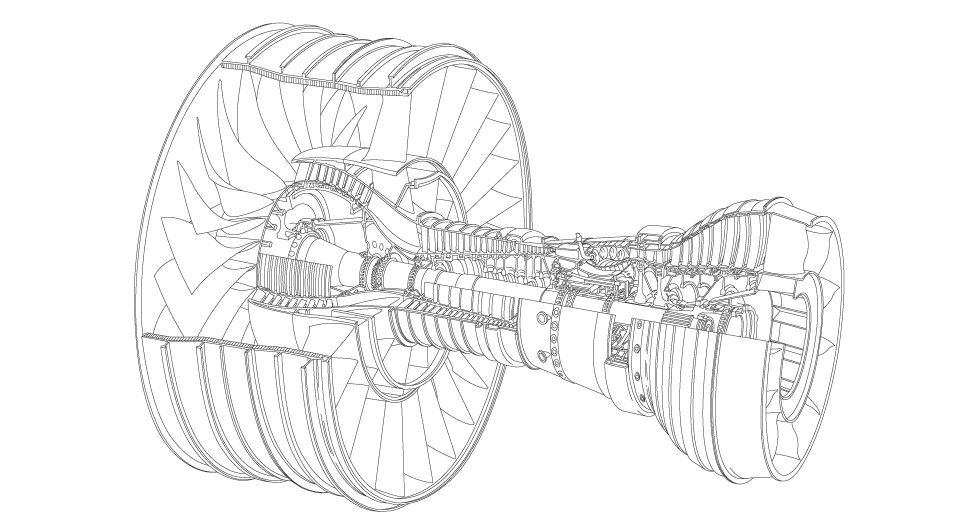

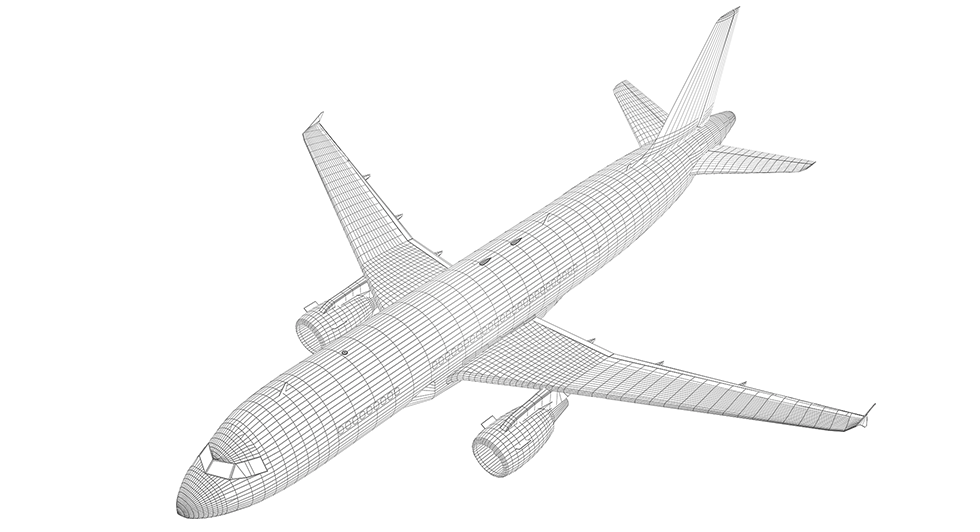

Fans at the front of the jet or gas turbine draw air into the engine. In fact for most large commercial airliners, a specific type of jet a "turbo-fan" as pictured is used. In this case only some of the the air is pulled through the engine cycle, the oversized fan at the front blows the rest straight out to deliver more thrust when required, but better economy in flight.

Air that is drawn into the engine is compressed through a series of rotating and fixed blades. Known as "rotors" and "stators" these blades can compress the air by 40 times, and this process generates an immense amount of heat.

The compressed and hot air is mixed with fuel and ignited in the combustion chamber. The mixture is carefully controlled to ensure that there is a constant flame. The burnt gases expand rapidly and move to exit the engine.

Before the expanding gases can exit the engine they flow through the turbine. The turbine consists of further blades and these gases spin them and the central engine shaft as they exit through to the exhaust. The shaft spins the fan blades at the front of the engine drawing in more air air and ensuring the process continues.

Anim1Block

Overview

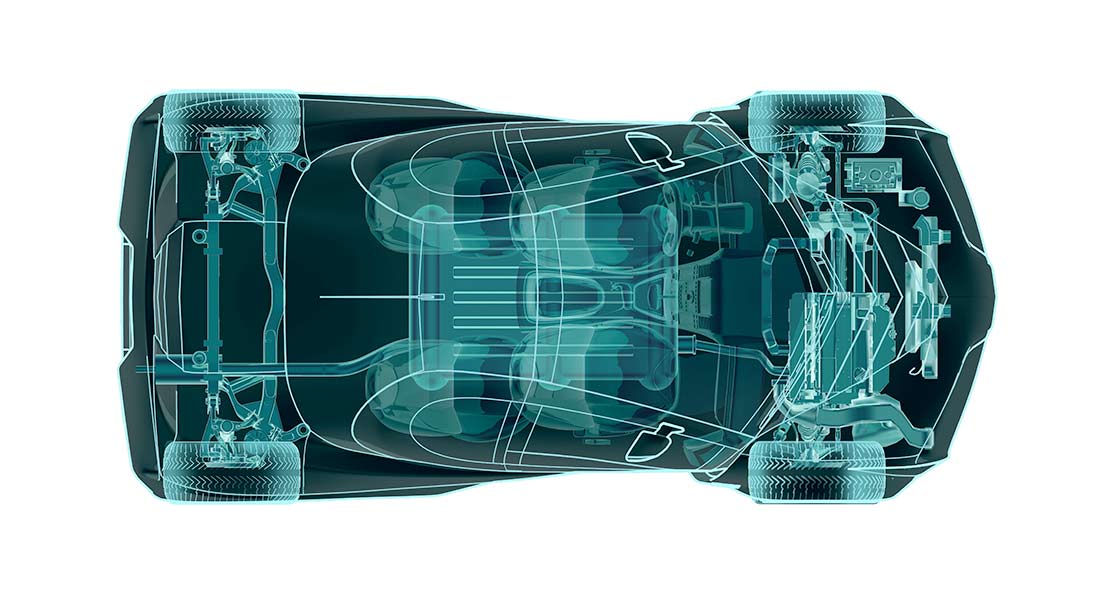

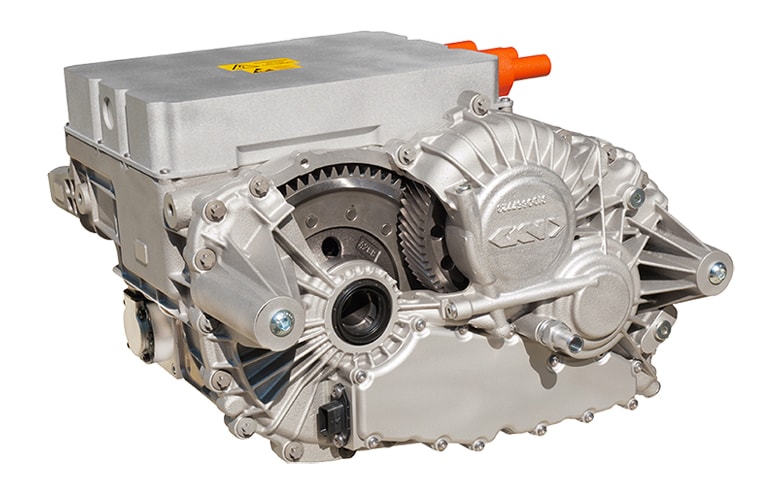

eDrive Concept

GKN's advanced technology concept eDrive system packages the electric motor, power inverter and eAxle reduction gearbox within a single casing.

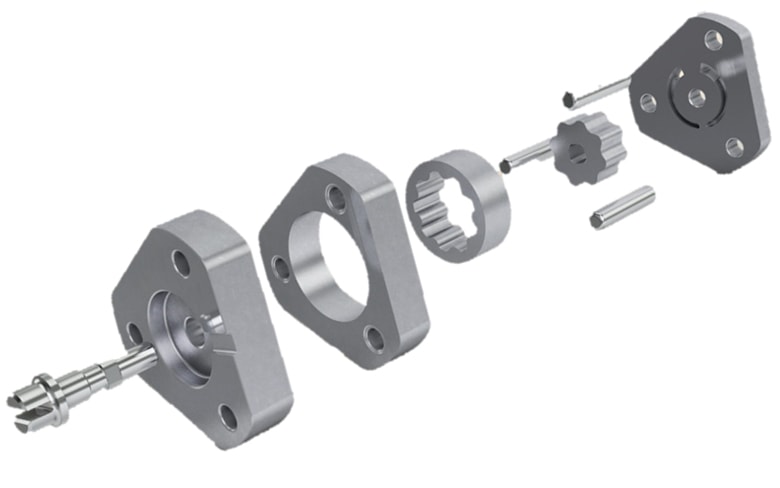

Sinter Pump G-Rotor set

GKN's G-Rotor Pump overcomes the known efficiency issue over the wide temperature range caused due to different material elongations. With the GKN unique "ALL-PM-approach" only PM steels are used and result in excellent hydraulic volumetric efficiency which enables a reduction of CO2 emissions.

Additive Manufacturing

GKN's additive manufacturing capabilities are allowing us and our partners to develop the next generation of automotive drivelines more rapidly.

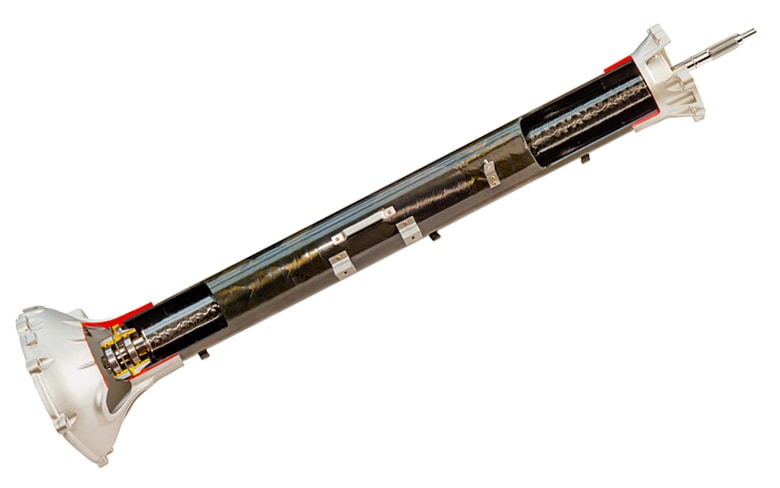

Carbon Fibre Propshaft

GKN has developed a lightweight, high performance carbon fibre propshaft for use on performance vehicles.

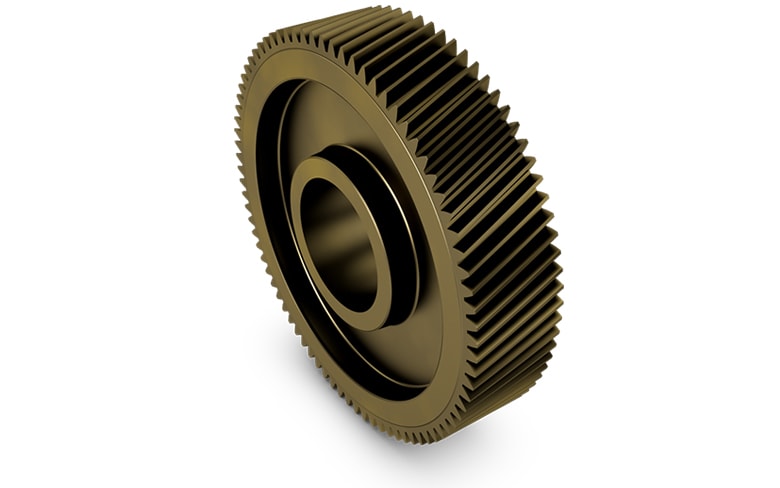

Sintered Rolled Helical Gears (eDrive gears)

Noise is a key consideration when developing systems for electrified vehicles as rpm rises and higher torque capacity is needed. GKN's Sintered Rolled Helical Gears with defined density distribution result in excellent Noise, Vibration and Harshness characteristics.